Powder Transfer Solutions: QVC vs ZKS Vacuum Conveyor/Transfer System

- protech solutions

- Oct 23, 2024

- 3 min read

Updated: Dec 3, 2024

What is Vacuum Conveying or Powder Transfer Systems?

Vacuum Conveying is the process of moving bulk dry materials, such as powders, from place to place using suction.

A Vacuum Conveyor is used to transfer dry powder or granular material. A vacuum conveyor is also known as a Vacuum feeder or vacuum transfer, powder transfer systems is a kind of dust-free airtight pipeline conveying equipment that transfers particles and powder materials by vacuum suction. It uses the difference of air pressure between vacuum and environment space to form gas flow in the pipeline, and drives the movement of powder materials, so as to complete powder conveying.

Features & Advantages

GMP Standard Qualified:

Our vacuum conveyors 100% meet GMP standard and can be used in related industries, like food, pharmacy, etc.

High efficiency and safe conveying:

The materials will be carefully conveyed to avoid any damage or abrasions.

Convenient Installation and simple operation:

The modular engineering design makes our vacuum conveyor very convenient to install or equipped with other machines. Even one inexperienced worker can acquire the control skill rapidly.

Dust-free working space:

The entire conveying process is fully secured to ensure no material leakage.

Low energy consumption and cost saving:

The vacuum conveyor uses energy-saving technology to minimize the production cost of plants.

QVC PNEUMATIC VACUUM CONVEYOR /TRANSFER:

The QVC Pneumatic vacuum conveyor is widely used in various industries for transferring bulk quantities of materials from one place to a different one. Pneumatic conveying systems uses vacuum suction to transport granular and powdery materials. It is widely used in food, feed, coating, pharmaceutical, chemical, ceramic, agricultural production scientific research, and other fields.

Working Principle:

First The vacuum transfer uses compressed air and by a vacuum, generator creates airflow (negative pressure), that pulls material through the feeding inlet.

Inside the pneumatic vacuum hopper, the air and material are separated. The clean air passes through a filter and is released into the air, while the material stays and falls into a storage area (the silo).

When it's time to load the material, the vacuum valve closes, and the unloading valve opens. This allows the material to move into the designated receiving equipment. The system uses a blowback airbag to clean the filter automatically, so it's ready for the next cycle.

After unloading, the system starts again by sucking in more material.

Specifications:

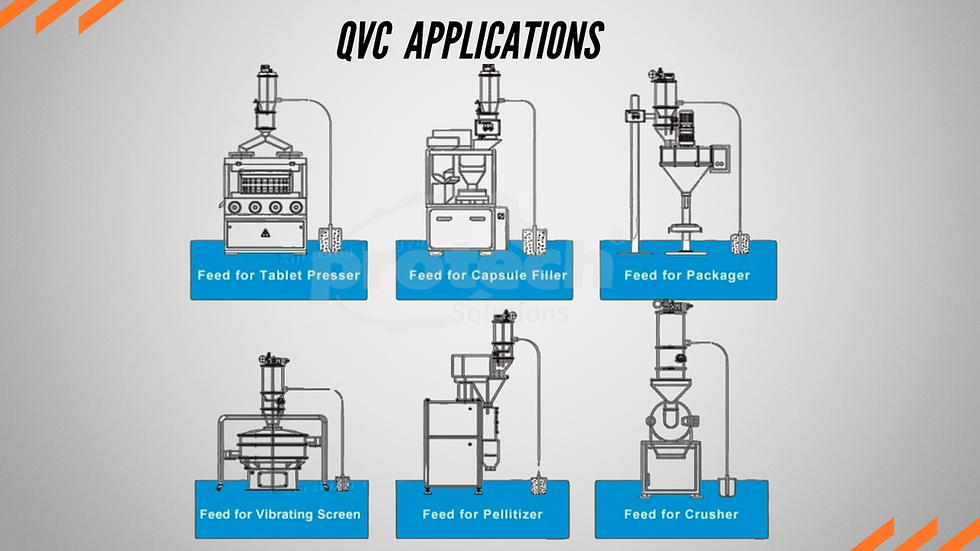

QVC VACUUM CONVEYOR APPLICATIONS

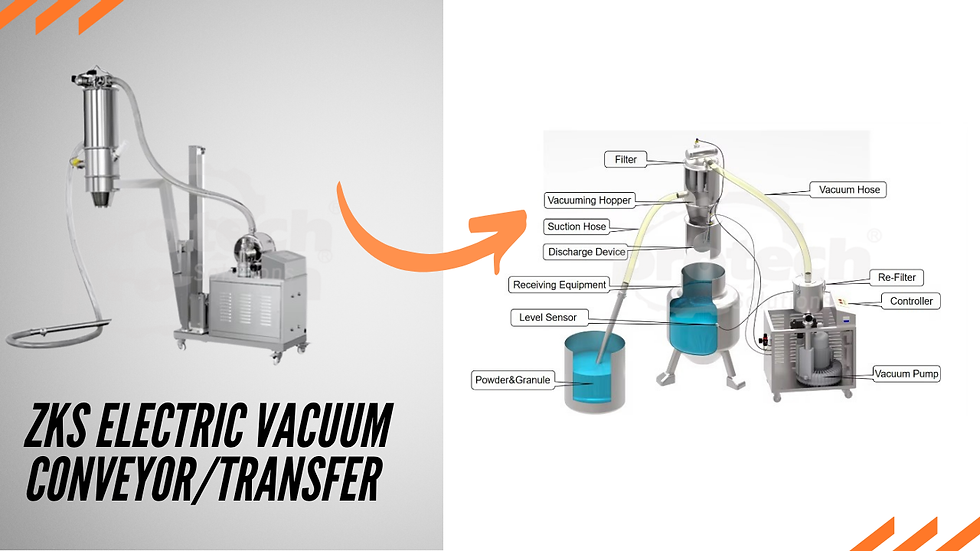

ZKS ELECTRIC VACUUM CONVEYOR/TRANSFER:

The ZKS Series Continuous Vacuum Conveyors are designed to safely and cleanly handle powders. They are used in the pharmaceutical, food, and chemical industries to move things like powder, dust, small pieces of material, and even tiny metal chips from milling machines. These conveyors can handle all of this without getting damaged.

Working Principle:

1. First When the air pump spins, it creates a vacuum (like a suction effect). This vacuum pulls the material into the suction port.

2. The material mixes with air and gets pulled through a suction pipe. It travels to a storage area(silo) in the loading machine.

3. A filter separates the material from the air completely.

4. Once the material fills the storage area (silo), the controller shuts off the power, stopping the vacuum feeder.

5. The door of the storage area (silo) opens automatically, and the material falls into the hopper (the next part of the machine).

6. Compressed air cleans the filter through a special valve called a pulse backflush valve.

7. The feeding of material starts again automatically when either the timer finishes or a sensor signals that more material is needed.

Specifications:

REMARKS: The conveying capacity is measured when the conveying tube is 4 meters long and the conveying material is flour. The longer the conveying tube, the lower the conveying capacity will be. Conveying capacity also has a significant relationship with the properties of the materials.

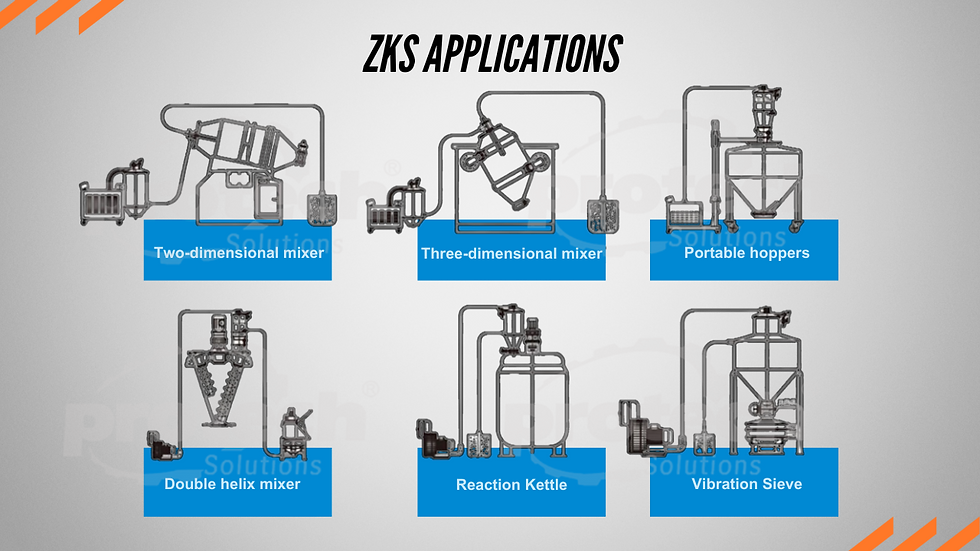

ZKS Applications:

Main Differences Between ZKS and QVC:

Both models have their strengths, with ZKS focusing on high-capacity, continuous processes and QVC offering flexibility for smaller, batch-oriented tasks. The choice between the two depends on the specific material volume and industry requirements.

The proper selection of a vacuum conveyor depends on different factors such as:

Being conveyed material :

Material characteristic: bulk density:

Conveying capacity:____kg/ hour

Conveying length:

Conveying height:

Intermittent or continuous feeding material

Voltage: ______ Phase ______V, Frequency:______HZ

In conclusion, vacuum conveyors offer an efficient and reliable solution for material handling across various industries, ensuring dust-free, safe, and streamlined operations. Whether you need a system for high-volume transfer or smaller, batch-oriented processes, choosing the right vacuum conveyor can significantly enhance your production efficiency and product quality.

If you're looking to implement or upgrade your vacuum conveying system, fill out the contact form below with the information about your project to discuss your specific requirements. Our team of experts will help you find the perfect solution tailored to your needs. Please send us your details, and let’s get started on optimizing your material handling process!

Comments